Description

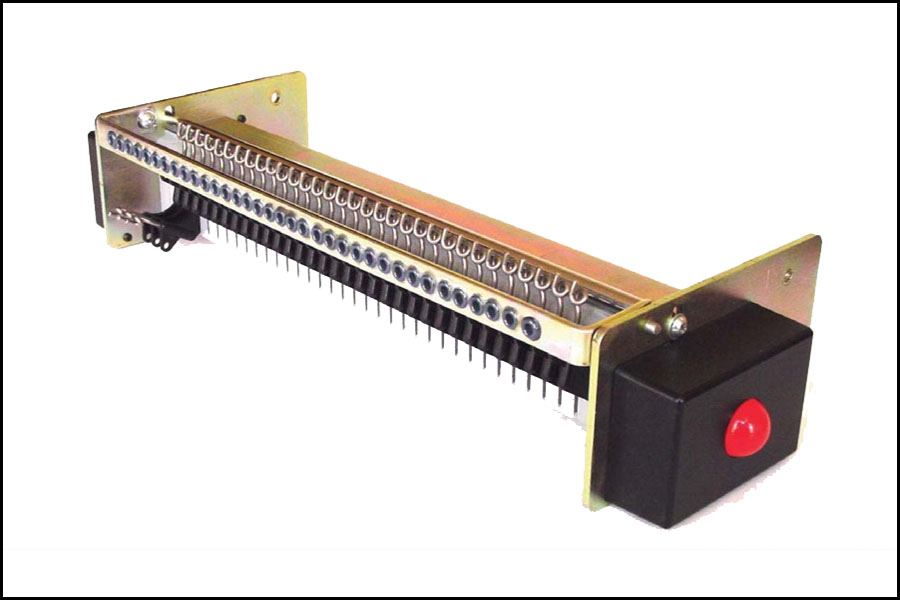

Dust-resistant design – conventional stop motions rely upon each dropper making or breaking an electrical circuit. However, these electrical contacts are prone to contamination by dust and oil resulting in false signals and so necessitating regular stripping and cleaning. The Ascotex stop motion greatly reduces this problem by using an infrared light beam to detect the position of the droppers.

Simple to install – can be easily integrated into your electrical control circuitry; one pair of wires feeds the power to the unit, whilst the other pair provides feedback by means of an open / closed relay switch within the unit.

Flexibility in design – custom built to suit your individual requirements with the following options:-

- Number of yarn ends (up to 100 ends at 10mm pitch, 70 ends at 14mm pitch)

- Pitch between yarns ( 10 & 14 are standard, other configurations possible)

- Jumbo LED indicator lamp available at either, or both, ends of the unit

- Positions temporarily not required can be simply “clicked” out of use

- Choice of guides on dropper arms – quick thread or closed eyelets

- Control leads can be positioned at ether end of the unit

- Failsafe circuitry in event of a fault or power failure

- Custom made fixing bracketry if required

- Choice of input / output guides

- 24vdc (standard) or 12vdc

- Anti-static option